5軸CNCマシン 現在、需要のある業界で広く使用されています 複雑な加工と高精度高度な多軸生産に移行するメーカーが増えるにつれて、市場における5軸CNCブランドの数は増え続けています。

しかし、選択肢が多すぎるため、適切なブランドを選ぶことはますます困難になっています。機械の安定性、長期的な精度、アフターサービスの違いは、機器が既に生産段階に入ってから、変更に多額の費用がかかるようになって初めて明らかになることが多いのです。

では、このような大規模な投資を行う前に、信頼できる 5 軸 CNC マシンのブランドをどのように特定すればよいのでしょうか?

この記事では、 主要5軸CNCマシンブランド15社主要なプレーヤーを比較し、生産ニーズに最適なオプションを絞り込むのに役立ちます。

さあ、始めましょう。

ブランド | 設立年 | 本部 | 特集 |

DMG森精機 | 1870 | ドイツ | グローバルハイエンドCNCリーダー、強力な5軸ポートフォリオ、高度な自動化およびデジタルソリューション |

マザック | 1919 | 日本 | 老舗CNCブランド、統合制御システム、強力なグローバルサービスネットワーク |

大隈 | 1898 | 日本 | 自社制御・駆動システム、高剛性マシン、強力な代理店ベースのサービス |

牧野 | 1937 | 日本 | 高精度加工に重点を置き、航空宇宙および金型用途に強み |

HAASオートメーション | 1983 | アメリカ合衆国 | 大規模生産、コスト効率の高いCNCマシン、幅広いグローバルユーザーベース |

DNソリューションズ | 1976 | 韓国 | 大手CNCメーカー、幅広い5軸ラインナップ、強力なグローバル展開 |

アマダ | 1946 | 日本 | 精密製造の背景、高度なエンジニアリングと自動化 |

ヤンセン | 2003 | 中国 | コスト効率の高い5軸ソリューション、強力な製造基盤、柔軟なカスタマイズ |

MCM | 1978 | イタリア | 特殊5軸加工センター、航空宇宙向けソリューション |

ヘルムレ | 1938 | ドイツ | 超高精度5軸マシン、最高品質のエンジニアリング |

カイロン | 1921 | ドイツ | 高速加工の専門知識、自動化対応CNCシステム |

グロブ | 1926 | ドイツ | 自動車と航空宇宙に焦点を当てた、高度な5軸生産システム |

ヒュンダイ WIA | 1976 | 韓国 | 統合製造グループ、幅広いCNC製品ラインナップ |

マイクロカット | 1983 | 台湾 | 精密CNCマシン、優れたコストパフォーマンス |

事業形態: 高級CNC工作機械メーカー

位置: ドイツ

設立年: 1870年(ドイツ)

メーカー紹介:

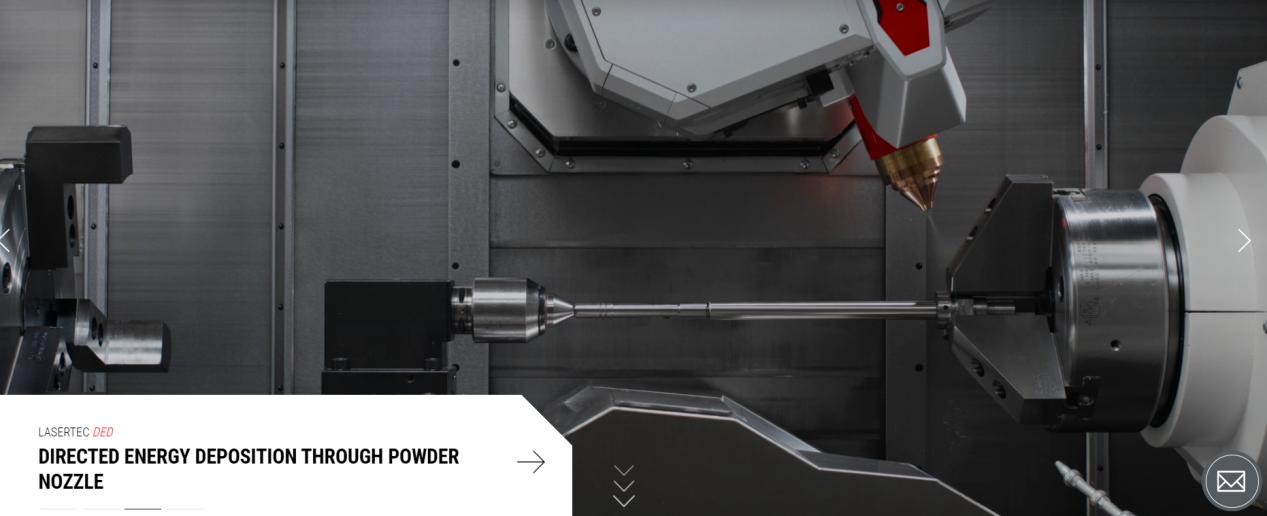

DMG MORIは、高精度工作機械の世界的リーダーであり、 44か国 と 124件の販売 サービス拠点と 17の生産工場 世界中で。

同社は13,500人以上の従業員を雇用し、「グローバルワンカンパニー”戦略と長期的な製造業の発展。

DMG MORIは、マシニングトランスフォーメーション(MX)という指針のもと、プロセス統合、自動化、デジタルトランスフォーメーション(DX)、グリーントランスフォーメーション(GX)を統合し、効率的で持続可能な生産を実現します。

DMG MORIは、トレーニング、修理、メンテナンス、スペアパーツの供給など、工作機械のライフサイクル全体にわたってお客様に包括的なサポートを提供します。

事業範囲:

5軸CNC加工センター

ミルターンおよびマルチタスクマシン

高精度CNCフライス盤

自動化システムと生産セル

デジタル製造およびソフトウェアソリューション

推奨理由:

DMG MORIは、最高レベルの5軸CNC性能、長期的な精度安定性、そして包括的なグローバルサービスサポートを求めるメーカーにとって理想的な選択肢です。深いエンジニアリング専門知識と高度な自動化機能により、高付加価値・高精度加工アプリケーションに特に適しています。

事業形態: 統合制御システムを備えた世界的なCNC工作機械メーカー

位置: 日本

設立年: 1919

メーカー紹介:

MAZAKは世界で最も確立された企業の一つです CNC工作機械メーカー、以上 100年の経験 工作機械の設計と製造。

MAZAKは、 5軸加工とマルチタスク技術工作機械、CNC制御、自動化、ソフトウェアを組み合わせた統合製造ソリューションを提供しています。MAZAKの強みは、高度な垂直統合であり、これには以下の社内開発も含まれます。 CNC制御システム、スピンドル、コアマシンコンポーネントを製造し、長期的な安定性と一貫性を保証します。

MAZAK は、設置やトレーニングからメンテナンスや技術サポートまで、機械のライフサイクル全体にわたってお客様をサポートします。

事業範囲:

5軸CNC加工センター

マルチタスクおよびミルターンマシン

高精度CNCフライス盤

CNC旋盤

自動化システムと統合製造ソリューション

推奨理由:

MAZAKは、数十年にわたるエンジニアリング経験と強力なグローバルサポートに支えられた信頼性の高い5軸CNC工作機械を求めるメーカーに最適です。垂直統合型生産、安定した機械性能、そしてライフサイクル重視のサービスにより、複雑かつ高精度な加工環境において信頼できる選択肢となります。

事業形態: 垂直統合型CNCマシンメーカー

位置: 日本

設立年: 1898

メーカー紹介:

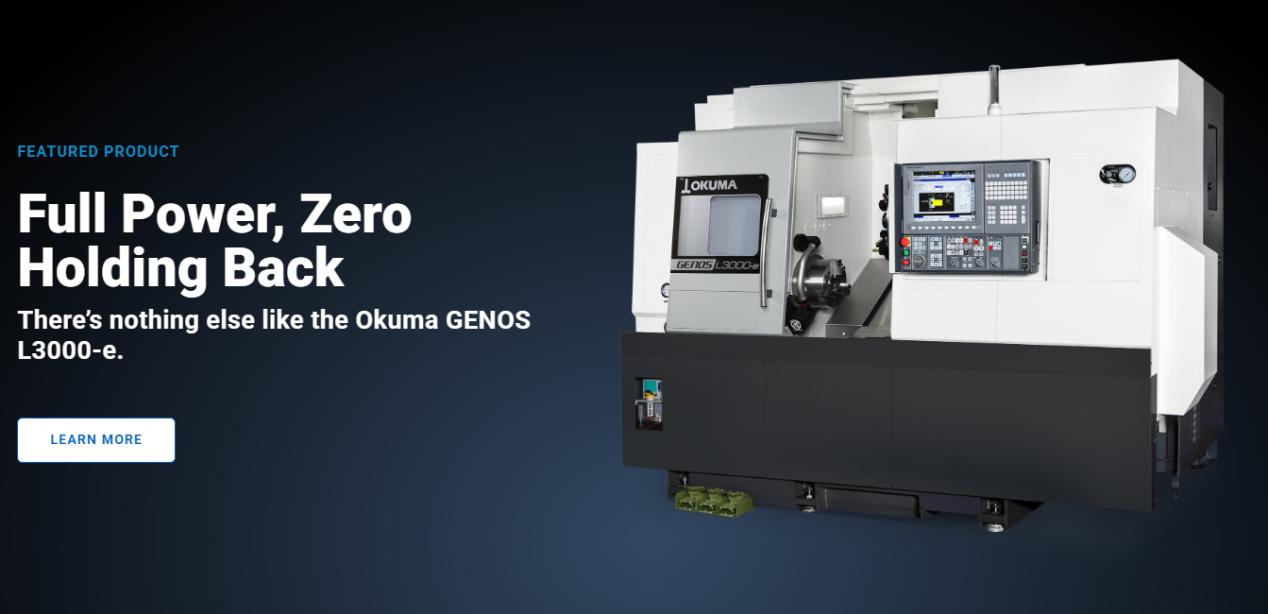

オークマは、日本のCNC工作機械メーカーとして長年の実績があり、 120年以上の経験 精密機械分野で。

同社は 複数の生産施設 当社は日本に拠点を置き、世界中のお客様をサポートするグローバルな販売・サービス ネットワークを維持しています。

OKUMAの強みは シングルソース製造哲学オークマは、CNC制御、サーボドライブ、スピンドル、機械構造といったコアコンポーネントを自社で開発・製造しています。この高度な垂直統合により、オークマは機械ラインナップ全体にわたって厳格な品質管理、安定した性能、そして長期的な精度を維持しています。

OKUMA は 5 軸加工の信頼性、熱安定性、構造的剛性を重視しており、その機械は要求の厳しい産業環境に適しています。

事業範囲:

5軸CNC加工センター

CNC垂直および水平マシニングセンター

CNC旋盤と複合加工機

統合CNC制御および駆動システム

自動化対応CNC製造ソリューション

推奨理由:

OKUMAは、長期的な機械安定性と完全なシステム統合を重視するメーカーにとって最適な選択肢です。ワンストップ製造体制、強力な熱制御技術、そして信頼性の高いグローバルサービスネットワークにより、精密加工と連続生産が求められる加工環境に最適です。

事業形態: 高精度CNC工作機械メーカー

位置: 日本

設立年: 1937

メーカー紹介:

マキノは、 プロセス主導の加工ソリューションの提供 同社は、独立した機器ではなく、機械を完全な製造システムの一部として構築することを重視し、機械設計、制御、ツール戦略、アプリケーションの専門知識を統合することで、信頼性の高い生産成果を実現します。

マキノの強みは、 エンジニアリング主導のアプローチ 精度、面品位、熱安定性に配慮した設計。機械構造、主軸システム、モーション制御を一体化したシステムとして設計することで、高精度かつ要求の厳しい加工環境においても安定した性能を実現します。

MAKINO は、特に厳しい公差とセットアップの削減が求められる複雑な部品の加工において、5 軸加工機能に重点を置いています。

MAKINO は、機械製造の枠を超えて、アプリケーションエンジニアリング、プロセス最適化、トレーニング、ライフサイクルサポートを提供し、お客様の生産性向上、リスク軽減、長期にわたる安定した製造パフォーマンスの実現を支援します。

事業範囲:

5軸CNC加工センター

高速・高精度 CNCフライス盤

水平型および垂直型マシニングセンター

航空宇宙および金型製造向けCNCソリューション

統合自動化およびプロセス最適化ソリューション

推奨理由:

MAKINOは、複雑な5軸アプリケーションにおける加工精度、表面品質、そしてプロセス安定性を重視するメーカーに最適です。エンジニアリングへの強いこだわり、航空宇宙産業および金型産業における実績あるパフォーマンス、そして包括的なアプリケーションサポートにより、MAKINOは高精度生産における信頼できるブランドとなっています。

事業形態: CNC工作機械メーカー

位置: アメリカ合衆国

設立年: 1983

メーカー紹介:

HAAS Automationは1983年に設立された米国に拠点を置くCNC工作機械メーカーで、 集中生産 南カリフォルニアで。

すべてのHaas製品は、 110万平方フィートの最先端製造施設一貫した品質と生産管理を保証します。

Haasのマシンは以下を通じて販売されています 170以上のハース工場 アウトレット(HFO)は、 60か国以上 世界中で。

グローバル HFO ネットワークは、機械のライフサイクル全体にわたって、ローカライズされた販売、サービス、トレーニング、技術サポートを提供します。

事業範囲:

5軸CNC加工センター

垂直および水平マシニングセンター

CNC旋盤

自動化対応CNCソリューション

一般産業用途向けCNCマシン

推奨理由:

HAAS Automationは、コストパフォーマンスに優れた信頼性の高い5軸CNCソリューションを求めるメーカーに最適です。大規模な製造能力、標準化された生産品質、そして広範なグローバル販売代理店ネットワークにより、アクセス性、サポート、そして予測可能な運用を重視する企業にとって、HAAS Automationは現実的な選択肢となります。

事業形態: 産業グレードのCNCマシンメーカー

位置: 韓国

設立年: 1976

メーカー紹介:

1976年に設立されたDNソリューションズ(旧斗山マシンツール)は、 40年以上の経験 CNC マシン製造業。

DNソリューションズは、 66カ国に140の販売ネットワーク同社は韓国、中国、ヨーロッパに複数の製造拠点を構え、大規模なグローバル生産をサポートしています。

DN ソリューションは、産業用途向けの高度な 5 軸加工ソリューションを含む、高剛性で自動化対応の CNC マシンに重点を置いています。

同社の機械は、世界中で自動車、航空宇宙、金型、エネルギー、重工業の用途に広く使用されています。

事業範囲:

5軸CNC加工センター

垂直および水平マシニングセンター

CNC旋盤

自動化統合CNCシステム

産業機械加工ソリューション

推奨理由:

DN Solutionsは、堅牢な構造設計と産業レベルの信頼性を備えた堅牢な5軸CNC工作機械を求めるメーカーに最適です。長年の製造実績とグローバルな生産拠点により、連続加工や高負荷加工環境において信頼できる選択肢となります。

事業形態: 工作機械メーカー

位置: 日本

設立年: 1946

メーカー紹介:

アマダは1946年に設立され、 70年の経験 精密製造機器分野。

当社は、精度、安定性、製造の信頼性を長期にわたって重視し、高精度の機械設計における強力なエンジニアリング基盤を確立していることで知られています。

AMADA は、工作機械、自動化、生産サポート システムを統合し、産業製造環境における効率と一貫性を向上させます。

同社のソリューションは、世界中の自動車、航空宇宙、精密部品、一般工業製造に広く応用されています。

事業範囲:

5軸CNC加工センター

精密CNC工作機械

自動化と統合製造システム

産業機械加工ソリューション

推奨理由:

アマダは、数十年にわたる機械製造の経験を基盤とし、安定性と精度を重視したCNCソリューションを求めるメーカーに最適です。強力なエンジニアリング基盤と統合型製造システムへの注力により、長期的な生産環境において信頼できる選択肢となります。

事業形態: コスト効率と精度に重点を置いたCNCマシンメーカー

位置: 中国

設立年: 2003

メーカー紹介:

YANGSEN は 2003 年に設立され、CNC マシン製造で 20 年以上の経験を誇ります。

同社は以下の製造施設を運営しています。 10万平方メートル以上700 人以上の従業員によって支えられています。

ヤンセンの年間生産能力は 5,000台以上のCNCマシン標準化された生産および品質管理システムによってサポートされています。

同社は ISO9001 品質管理基準と保持 100件以上の特許継続的な研究開発投資を反映しています。

より多い 年間売上高の7.5% 独立した研究開発能力を促進し、さまざまなCNC工作機械の精度と手頃な価格を継続的に改善するために、研究開発資金として毎年割り当てられています。

YANGSEN CNC マシンは 20 か国以上に輸出されており、さまざまな産業分野の世界中の顧客にサービスを提供しています。

事業範囲:

5軸CNC加工センター

立形マシニングセンター

ガントリー加工センター

CNC旋盤とフライス盤

推奨理由:

YANGSENは、競争力のある価格で高精度CNC工作機械を求めるメーカーにとって最適な選択肢です。台湾や日本製の同等機種の95~120%の性能を50~70%のコストで実現し、安定した品質と充実したアフターサービスに裏打ちされた高い価値を提供します。

事業形態: 航空宇宙に特化した5軸CNCマシンメーカー

位置: イタリア

設立年: 1976

メーカー紹介:

MCMは1976年に設立され、イタリアのCNC工作機械メーカーで、 50年の経験 高度な多軸加工技術。

同社は高性能5軸加工センターを専門とし、 柔軟な製造システム 複雑で大規模な構造の部品向けの FMS (Finishment Manufacturing System)。

MCM は、高付加価値製造のために工作機械、自動化、生産統合を組み合わせたシステムレベルのソリューションに重点を置いています。

同社の CNC システムは、航空宇宙、防衛、エネルギー、高度な機械工学のアプリケーションで広く使用されています。

事業範囲:

5軸CNC加工センター

大型・高剛性CNCマシン

フレキシブル製造システム(FMS)

航空宇宙および複雑部品加工ソリューション

推奨理由:

MCMは、航空宇宙産業や複雑な大型部品の加工に注力するメーカーにとって最適な選択肢です。5軸システムと柔軟な製造ソリューションへの長年の特化により、複雑性が高く高付加価値の生産環境に最適です。

事業形態: ハイエンド5軸CNC加工センターメーカー

位置: ドイツ

設立年: 1938

メーカー紹介:

1938年に設立されたHERMLEは、 80年の経験 精密CNC機械製造。

同社は高性能に特化している 5軸加工センターすべての機械はドイツで開発・製造されています。

HERMLE は、厳格な品質管理と長期的な精度安定性を確保するために、社内生産の深さを重視した最新の製造拠点を運営しています。

同社の 5 軸 CNC マシンは、航空宇宙、医療技術、金型、精密エンジニアリング、ハイエンド製造業で幅広く使用されています。

事業範囲:

5軸CNC加工センター

高精度フライス加工ソリューション

自動化統合5軸生産システム

複雑で高精度な部品のためのCNCソリューション

推奨理由:

HERMLEは、最高レベルの5軸加工精度と長期的な精度安定性を求めるメーカーにとって理想的な製品です。5軸技術への特化とドイツ独自の製造基準により、ハイエンドかつ公差が極めて厳しいアプリケーションに最適な選択肢となっています。

事業形態: 高速・高精度CNC加工センターメーカー

位置: ドイツ

設立年: 1921

メーカー紹介:

1921年に設立されたCHIRONは、 ドイツのCNC工作機械メーカー と 100年以上の経験 精密機械工学の分野で。

同社は、 高速かつ高精度 複雑な部品製造のための高度な 5 軸ソリューションを含む CNC 加工センター。

CHIRON は、特に大量生産および精密製造環境において、短いサイクルタイム、加工精度、および生産効率に重点を置いています。

同社の CNC マシンは、自動車、航空宇宙、医療技術、精密部品、一般工業製造分野で幅広く使用されています。

事業範囲:

5軸CNC加工センター

高速立形マシニングセンター

精密生産と量産向けCNCソリューション

自動化対応加工システム

推奨理由:

CHIRONは、生産性と精度を最適化した高速5軸CNC工作機械を求めるメーカーに最適です。長年にわたるエンジニアリングの実績と効率性へのこだわりにより、量産および精密加工アプリケーションにおいて信頼できる選択肢となります。

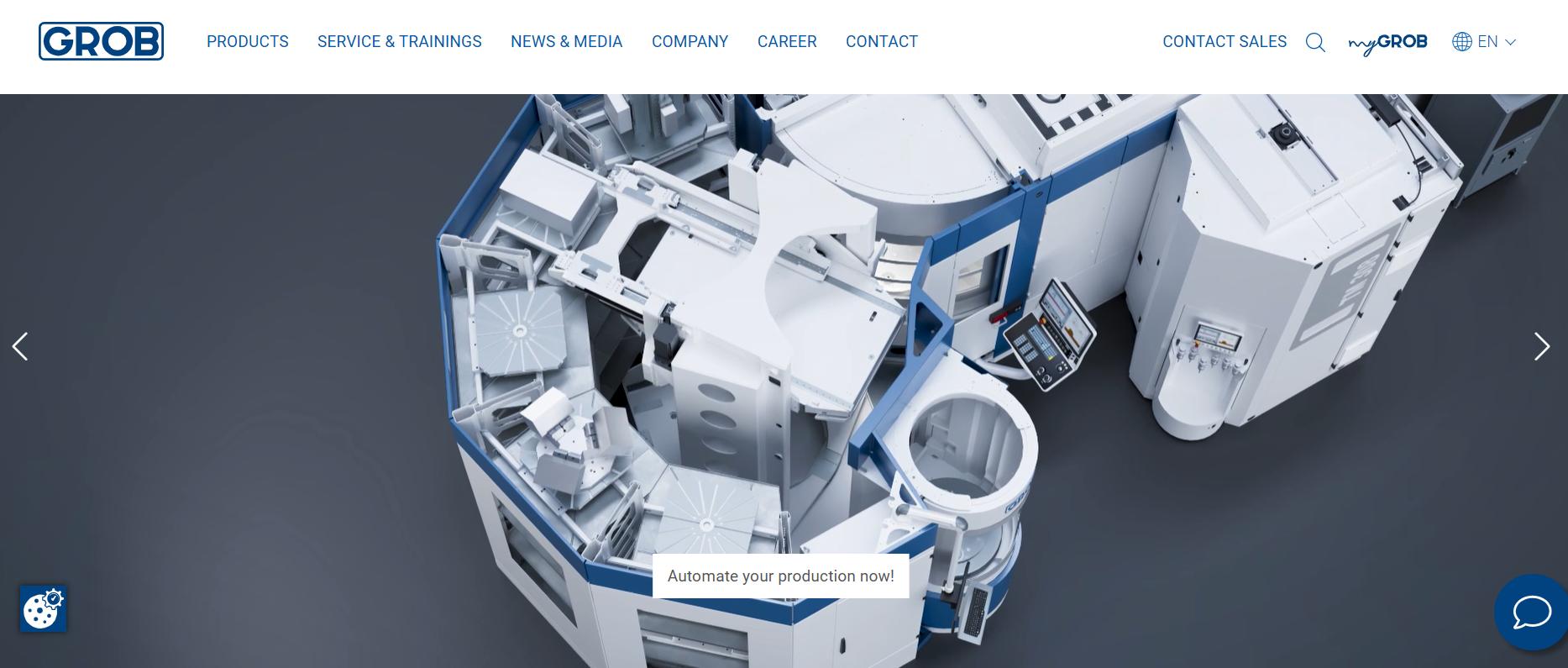

事業形態: システムレベルの5軸CNCマシンおよび生産ソリューションメーカー

位置: ドイツ

設立年: 1926

メーカー紹介:

GROBは1926年に設立され、ドイツの工作機械メーカーで、 100年の経験 工業製造システムにおいて。

同社は、機械、自動化、完全な生産ラインを組み合わせたシステム指向の 5 軸 CNC ソリューションで広く知られています。

GROBは、 高精度・高効率 機械加工、特に 大規模で複雑な産業部品.

同社の 5 軸 CNC システムは、世界中の自動車、航空宇宙、e モビリティ、高度な製造アプリケーションで幅広く使用されています。

事業範囲:

5軸CNC加工センター

横型マシニングセンター

ターンキー生産システムと自動化ライン

統合製造および組立ソリューション

推奨理由:

GROBは、スタンドアロンマシンではなく、包括的な5軸CNC生産システムを求めるメーカーに最適です。長年の実績とシステムレベルのエンジニアリング能力により、大量生産や複雑な製造環境に最適な選択肢となります。

事業形態: 大規模産業用CNCマシンメーカー

位置: 韓国

設立年: 1976

メーカー紹介:

HYUNDAI WIAは1976年に設立され、韓国に拠点を置くCNC工作機械メーカーで、 40年の経験 産業機械製造業。

同社は現代自動車グループの一員であり、強力な産業支援と 大規模な製造能力.

HYUNDAI WIA は、安定性、耐久性、大量生産の要件に重点を置いて、産業グレードの CNC マシンを開発、製造しています。

同社のCNCマシンは、自動車、航空宇宙、エネルギー、一般産業の製造業、特に 大量生産環境.

事業範囲:

5軸CNC加工センター

垂直および水平マシニングセンター

CNC旋盤

大量生産向け産業用CNCソリューション

推奨理由:

HYUNDAI WIAは、大規模な製造グループに支えられた安定した産業グレードのCNCマシンを求めるメーカーにとって最適な選択肢です。強力な製造実績と耐久性へのこだわりにより、大量生産や連続加工アプリケーションに最適です。

事業形態: 価値重視の精密CNC機械メーカー

位置: 台湾

設立年: 1983

メーカー紹介:

MICROCUTは1983年に設立され、台湾に拠点を置くCNC工作機械メーカーで、 40年の経験 精密機械製造業。

このブランドは信頼性と 費用対効果の高いCNCソリューション加工精度、構造安定性、競争力のある価格のバランスを実現します。

MICROCUTは 精密加工センター 多軸 CNC ソリューションを提供し、プレミアムレベルのコストをかけずに一貫したパフォーマンスを必要とするメーカーにサービスを提供します。

同社の CNC マシンは、自動車部品、金型、一般的な精密エンジニアリング、工業製造アプリケーションで使用されています。

事業範囲:

5軸CNC加工センター

垂直および水平マシニングセンター

精密CNCフライス盤

一般産業用途向けCNCソリューション

推奨理由:

MICROCUTは、コストパフォーマンスに優れた実用的な5軸CNCソリューションを求めるメーカーにとって、確かな選択肢です。長年の製造実績と信頼性の高い精度へのこだわりにより、中小規模のメーカーやコスト意識の高い生産環境に最適です。

1. 5 軸 CNC マシンを選択する際にブランドが重要なのはなぜですか?

5軸CNC工作機械は、複雑な運動学、回転軸、そして長期的な精度管理を必要とします。確立されたブランドは通常、より豊富なエンジニアリング経験、より成熟した構造、そしてより優れたライフサイクルサポートを備えており、生産リスクと予期せぬダウンタイムを軽減します。

2. 購入者は 5 軸 CNC ブランドの実際の能力をどのように評価できますか?

購入者は仕様を超えて、製造経験、工場の規模、グローバルなサービス ネットワーク、インストール ベース、類似業界での検証済みのアプリケーション事例などの測定可能な要素に重点を置く必要があります。

3. 5軸CNC加工においてアフターサービスはどのような役割を果たしますか?

アフターサービスは非常に重要です。5軸工作機械には、専門家による設置、校正、トレーニング、そして長期的な技術サポートが必要です。強力な地域サービスネットワークを持つブランドは、ダウンタイムとメンテナンスリスクを大幅に削減できます。

4. 高価な 5 軸 CNC マシンは常に良い選択でしょうか?

必ずしもそうではありません。価格が高いのは、多くの場合、ブランドポジショニングや高度な機能を反映していますが、最適な選択はアプリケーションのニーズによって異なります。多くのメーカーにとって、信頼性が実証された費用対効果の高いブランドは、総所有コスト(TCO)の削減につながる可能性があります。

5. マシン本体以外に購入者が考慮すべきことは何ですか?

購入者は、マシンに加えて、ツールの互換性、ソフトウェアのサポート、トレーニングの利用可能性、スペアパーツの供給、およびサプライヤーの長期的な安定性を評価して、持続可能な生産を確保する必要があります。

世界の市場には、多くの信頼できる 5 軸 CNC マシン ブランドが存在し、現代の製造業全体にわたる高精度で複雑な加工要件に対応する高度なソリューションを提供しています。

航空宇宙、自動車から金型製造、精密エンジニアリングに至るまで、これらのサプライヤーは、要求の厳しい生産環境をサポートするために、精度、効率、長期的な信頼性のバランスが取れた機械を提供しています。

加工能力をアップグレードする準備はできていますか?

手を差し伸べる 認定された 5 軸 CNC マシン サプライヤーに連絡して、アプリケーションのニーズについて話し合い、適切なソリューションを評価し、生産目標に最適なパートナーを見つけてください。