製造業やエンジニアリングの現場では、円筒状のワークを切削するための必須ツールとして旋盤が不可欠です。これらの機械は、旋削、面取り、溝入れ、面取りなど、様々な金属加工作業に効果的に対応し、精密部品の製造にも活用できます。

現代の CNC旋盤 ツールチェンジャーによる自動化により、機械は作業要件に応じて異なる工具を切り替えることができます。金属除去率を最大化し、加工製品において高精度な寸法と高品質な表面仕上げを実現するには、適切な旋盤工具を選択する必要があります。

以下の記事では、CNC 旋盤センターで使用される一般的な旋盤工具 15 種類を、その基本的な特性と使用目的とともに紹介します。

外径旋削工具は、外径溝入れ工具および外径旋削工具として機能し、CNC旋盤において最も一般的な工具です。外径旋削工具は、スピンドル内で位置合わせされた円筒形部品の外側の材料を削り取り、所定の寸法に仕上げます。

外径旋削工具のインサートは、特定の角度に研磨された鋭利な切れ刃を備えており、最小限の切削抵抗で金属切粉をせん断するように設計されています。工具をワークに対して垂直に送り込むことで、正確な量の材料を除去し、目標径を達成できます。これらの工具は、三角形、菱形、四角形、丸形など、様々なインサート形状で提供されています。

外径旋削加工では、リード角、すくい角、ノーズ半径といった工具形状要因によって優れた表面仕上げが得られます。CNCプログラマーは、ワーク材質に基づいて速度、送り速度、切込み深さなどの切削パラメータを最適化し、荒加工と仕上げ加工において工具がワークに効率的に食い込むようにします。

外径旋削工具は外面を加工しますが、内径旋削工具(ボーリングバーとも呼ばれます)は円筒状のワークピースの内面を加工します。これらの工具は、溝、穴、その他の内部形状を高精度な寸法と低い表面粗さで切削するように設計されています。

これらの工具は、旋盤の主軸に取り付けられたワークピースの内部にアクセスできるように、長いバレルを備えています。切削力はバーを介して伝達されますが、バーは加工中にたわまないよう十分な剛性を備えていなければなりません。内径旋削工具インサートは、金属のせん断加工とボーリング加工時の切削負荷に対応するために最適化された形状を備えています。

CNC旋盤は、縦方向と横方向の補間動作を組み合わせることで、非常に厳しい公差の穴加工を可能にする内径旋削工具を備えています。単純な貫通穴加工に加え、プログラムされた工具パスに基づいて、内径にトレパニング、形状、溝、アンダーカットなどの精密なパターンを形成することもできます。

ボーリングバーは、既存の穴の正確なサイズ調整、仕上げ、または拡大に特化した内径旋削工具の一種です。自動車、航空宇宙、その他のエンジニアリング部品に必要な高精度の穴加工アプリケーションにおいて重要な役割を果たします。

剛性ボーリングバーは、正確なボーリング結果と穴の真円度に不可欠なたわみを最小限に抑えます。深穴内での大きなオーバーハングを可能にすることで、切削アクセスを向上させます。また、ボーリングバーには特殊なインサート形状が採用されており、使用条件に応じた低切削速度でも材料を効率的にせん断できます。

CNC旋盤では、従来のドリル加工やリーマ加工では達成できない、重要な部品に求められる厳しい穴サイズ、仕上げ、位置公差を実現するために、ボーリングバーが使用されます。ボーリング加工は、下穴に存在する歪みや位置ずれも除去します。加工者は、仕上げ穴の期待される寸法精度と表面品質を得るために、ボーリングの送り速度と切込み深さを慎重に選択する必要があります。

溝入れ工具とも呼ばれる突切り工具は、CNC旋盤において、完成したワークピースを余剰材料(残材とも呼ばれる)から分離するという重要な作業を行います。鋭利なインサートを用いてワークピースの周囲に深く狭い溝を切削することで、最終的に完成した部品を折り取る、つまり「切り離す」作業を容易にします。

これらの工具は、高度な形状と適切な角度を備えており、連続した切りくずが発生する難削材でもスムーズに貫通します。工具に十分な圧力をかけることで、ワークピースの中心に向かって深い溝を段階的に加工し、底面で残留物が破断するまで加工できます。

CNCアプリケーション用の突切り工具は、最適なクリアランス、チップブレーカー、放熱設計、そして切断プロセス中に発生する大きな切削力に耐える強度を備えています。剛性の高い工具保持インターフェースも、たわみを最小限に抑える上で重要な役割を果たします。適切な速度と送り設定により、突切り工具は高い再現性と安定した溝寸法を実現します。

面取り工具とも呼ばれる エンドミルCNC旋盤において、旋盤軸に対して垂直なワーク端面を正確に加工するために、面取り加工は重要な役割を果たします。この面取り加工により、片方の端面を滑らかな表面に仕上げ、外部または内部のフィーチャを加工する前に、ワークの長さを必要な寸法に正確に調整します。

フェーシングツールインサートは、端面切削加工に適した形状を特徴としています。狭い切込み幅で連続した軸方向パスで材料を切削し、滑らかで平坦な面を迅速に生成します。適切な切れ刃のすくい角により、切りくず形成が容易になり、繊細なワーク端面の加工硬化を防止します。

CNCプログラマーは、ワークピースの硬度に基づいて、面削りの送り速度、回転数、深さのパラメータを決定します。面削り中の温度上昇を最小限に抑え、過度の寸法誤差を回避するために、多くの場合、クーラントが使用されます。面削り工具はワークピースの形状を確立し、穴あけ、ボーリング、溝入れなどの後続加工で正確な結果が得られるようにします。

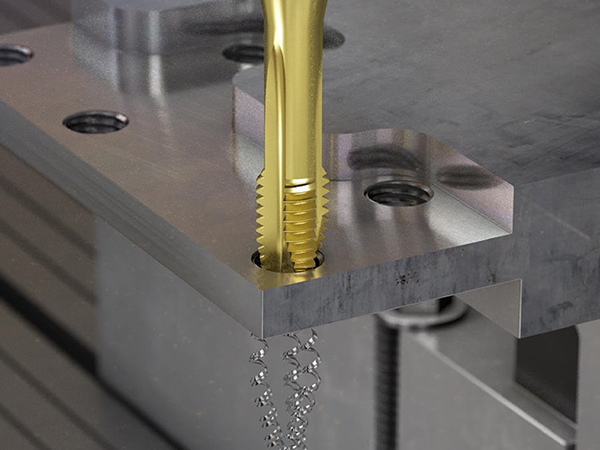

精密旋削加工されたワークピースの組み立てや締結においては、内面または外面へのねじ切りが一般的に求められます。CNC旋盤に搭載された専用のねじ切り工具は、プログラムされたピッチと深さに基づき、シングルポイントインサートカッターを用いて、正確な螺旋状の溝やねじを切ります。

ねじ切りインサートは、各パスで徐々に材料を除去し、正しいプロファイルのV字型ねじを生成するために必要な適切な形状角度を備えています。ねじ切り旋削工具には、部品設計のニーズに応じて、メートルねじ、UNFねじ、UNCねじ、またはその他の標準ねじ形状を切削するためのインサートが付属しています。

CNCシステムにより、ねじ切り工具はねじゲージや相手部品に正確に一致するねじ山を加工できます。従来の60°ねじに加え、アクメねじ、バットレスねじ、その他のねじ山も、ツールパス戦略に基づいてCNC旋盤で正確に切削できます。クーラントは構成刃先を防止し、ねじ山の仕上がりを向上させます。

ローレット加工は、旋盤加工された部品の表面に凹凸をつける重要な二次加工です。グリップ力を高めるために、表面に凹凸模様を形成します。一般的な例としては、ナット、ハンドル、操作部などのグリップ部分があり、滑りのない操作のために触覚的な摩擦が求められます。

ローレット加工工具は、1列または2列の鋭利なピラミッド型の刃で構成されており、ワークにダイヤモンド型、直線型、その他の美しい模様を正確に刻み込むことができます。工具をワークに対して垂直に送り、圧力をかけることで、刃が材料を押しのけ、必要なローレット加工面を冷間成形します。

CNCローレット加工は、手作業では不可能なパターン寸法と深さの均一性を優れた精度で制御できます。工具を交換することで、1つのワークピースに異なるローレットパターンを施すことができます。ローレット加工は、見た目の魅力と触感に加え、エンボス加工の下にある加工痕を隠す効果もあります。

溝入れ加工は、CNC旋削加工された部品に、様々な用途の外側または内側の円周溝を形成するために使用されます。部品の設計ニーズに基づき、シール機能のためのOリングの取り付け、仕切りの作成、保持リング溝、オイルリザーバーなどが含まれます。

溝入れ工具は、スローアウェイチップを備えたコンパクトなカッターヘッドで構成され、様々な幅の工具が用意されています。工具をワーク軸と平行方向に補間することで、四角形またはR形の溝底形状を持つ狭い溝を正確に切削できます。

一般的な溝入れ寸法は、幅1~6mm、深さ最大5mmです。溝入れインサートは、適切なリード角、チップブレーカー、その他の形状要因を備えており、軸方向または径方向の加工時に連続した切りくずを生成します。溝入れ工具と突切り工具は、このような深い高負荷加工に最適化された設計要素をいくつか備えています。

鋭利なエッジや角を持つ部品は、機能面や安全性の観点から、適切なエッジ処理、つまり「面取り」が必要となることがよくあります。例えば、面取りは危険な鋭利エッジを除去したり、嵌合部品の組み立てを容易にするためのリードインを確保したりします。また、角にかかる応力を最小限に抑え、亀裂の発生を防ぎます。

面取り工具は、適切な形状の刃先交換式チップを用いて、精密な刃先処理を行います。ワークの角に沿って補間加工することで、高い再現性で均一な面取りを実現します。30°、45°といった一般的な面取り形状はもちろん、部品の要件に合わせてカスタマイズされた角度も、CNCシステムで容易に加工できます。

旋盤での面取りフライス加工は、エッジ仕上げを向上させ、出口バリがあれば除去します。これにより、後続のハンドリング時に手を切るのを防ぎ、美観も向上します。重要な用途では、CNC面取り加工により、ワークピースのすべてのエッジが均一に加工され、手作業によるバリ取り工程のばらつきが排除されます。

フォーミングツールは、CNC旋盤に、従来の旋削インサートでは不可能な、複雑で非円筒形のプロファイルを加工する特別な機能を提供します。フォーミングツールには、ワークピースの希望するプロファイルの鏡像を特徴とするフルフォームインサートが付属しており、回転するブランクにこの形状を押し付けることで加工を行います。

成形旋削加工では、最適化された送り速度と切込み深さを組み合わせることで、材料をプロファイル全体に均一に押し出し、所望の複雑な形状をワークピースに再現します。金属の切削は行わず、せん断と冷間加工を組み合わせることで、予成形形状に正確に変形させます。

ダイヤモンドやその他の多結晶インサートは、これらの加工に必要な高圧成形時の摩耗を防ぎます。適切な工具保持剛性とプロセスパラメータを使用することで、成形工具は複数の製造工程を統合し、複雑な部品の製造サイクルを短縮するのに役立ちます。

CNC 旋盤センターには、ワークピースの連続加工操作の一環として穴を開けるための強力なドリル機能が組み込まれていることがよくあります。 ドリルツール 専用の掘削機が不要になり、ワークフローの時間が節約され、精度が向上します。

CNC旋盤での穴あけ加工には、刃先交換式超硬インサートを備えたドリルが一般的に使用されています。高い切削速度と、穴の位置精度を維持するために必要な剛性を備えています。工具本体にクーラントポートが設けられており、切りくず排出性が向上し、穴あけ加工中の構成刃先の発生を防ぎます。

強力なプログラム可能なスピンドルモーターにより、ドリル工具は精密部品の要件を満たす真直度と表面仕上げで深穴を加工できます。CNCシステムは、穴径と深さに基づいて、送り、速度、ペックドリルサイクルを最適化します。さらに、工程内での自動ゲージチェックにより、品質管理がさらに向上します。

リーマ加工は、CNC旋盤における重要な仕上げ工程であり、下穴の精度と表面仕上げ品質を向上させます。リーマ加工は、最初のドリル加工で生じた残留誤差を平滑化しながら、穴サイズを微細に拡大します。

リーマは、非常に厳しい直径公差を持つ精密工具で、低速で使用して高精度の穴寸法を実現します。リーマ加工では、わずか数千分の1インチしか切削しないため、穴仕上げ時の歪みリスクを排除できます。チャタリングマークが穴表面に転写されるのを防ぐには、高い剛性が不可欠です。

CNCリーマ加工により、穴径精度はドリル加工だけでは達成できないレベルまで向上します。これにより、ベアリングシャフトや嵌合部品を高精度な干渉嵌合によりスムーズに挿入できます。また、リーマ加工された穴は真円度と円筒度も向上し、厳しいアプリケーションニーズにも応えます。

旋盤加工されたワークピースの多くは、特殊な用途のために、旋盤軸に沿って徐々に径が小さくなるテーパー形状をしています。テーパー旋削工具は、CNC旋盤で協調補間動作を用いて、精密な外径テーパーまたは内径テーパーを加工することに特化しています。

これらのシングルポイント切削工具は、最適化された刃先処理が施されたインサートを採用し、円錐形状の成形時に発生する連続的な深さ変化に対応します。テーパー旋削加工では、直径を縮小するための軸方向送りと、円錐の長手方向に沿った荒加工/仕上げ加工のための半径方向送りを同時に調整します。

CNCプログラムは、直線テーパーに加え、適切なツールパスを使用することで、曲線テーパーや段付きテーパーなどの複雑な形状も生成できます。カスタムツールベクトルを作成することで、特殊な形状の工具や手動セットアップを必要とせずに、特定の部品設計に必要な不規則なテーパーを生成できます。

ねじ切りフライス加工は、特に大量生産において、ねじ山加工におけるシングルポイントねじ切り旋削加工の効率的な代替手段として登場しました。ねじ切りフライス加工は、ねじ山の形状を再現する歯形を持つインサートを備え、軸方向の補間運動を利用してフライス加工によりねじ山を生成します。

スレッドミルは様々なサイズがあり、メートル法またはインチ法の様々な形状とピッチのねじを切削できます。旋削加工よりも生産性が高く、複数のワークピース間での精度の一貫性も向上します。また、スレッドミル加工では、適応性の高いCNC旋盤でねじを交換する際に専用工具を使用する必要がありません。

高度な CNC プログラムは、ねじピッチ、部品材料の硬度、カッターの直径などに基づいて、ねじフライス加工操作の最適な送り速度とスピンドル速度を決定します。クーラントにより構成エッジが防止され、長期にわたる生産実行でもきれいで途切れないねじが確保されます。

ブローチング工具は、複数の刃を備え、一連の軽い切削によって正確な順序で材料を切削するように設計されています。CNC旋盤で使用され、厳密なサイズと表面仕上げの仕様が求められる内径キー溝やスプラインの切削に使用されます。

各ブローチ刃は、キー溝/スプライン寸法に沿って材料の小さな層をせん断するのに最適化された、段階的に高さが増す形状を特徴としています。ブローチは、複雑な形状を仕上げる際に、他のフライス加工方法では達成できない高精度を実現します。

CNCブローチ加工は、工具の過負荷を伴わずに金属を迅速に除去するための最適化された機械設定により、生産性を向上させます。また、高い再現性でプログレッシブブローチ加工を自動実行することも可能です。ブローチ加工された内径プロファイルは、ピン、シャフト、ギアを遊びやバックラッシュエラーなく位置決めするための精密な嵌合構造を備えています。

この記事では、精密加工アプリケーションでよく使用されるCNC旋削工具について、単純な面削りや旋削から複雑な内面ブローチ加工まで、幅広く解説しました。これらの旋盤切削工具の独特な形状と動作原理を理解することで、さまざまな加工要件に最適な工具を選択するための重要な知見が得られます。

工具の性能とワーク材質に応じて動作パラメータを最適化することが、生産性を最大化する鍵となります。切削工具の材質、コーティング、そしてスローアウェイチップの設計の進歩により、現代のCNC旋盤で可能な加工範囲は拡大し続けています。これにより、複数の工程を一つのセットアップに統合し、柔軟で正確かつ費用対効果の高いソリューションを実現できます。